Nigeria’s Imported Wood Woes: Are Our Plywood and Flute Panels Shrinking in Quality AND Size? 🇳🇬

Is your latest furniture project feeling a little... flimsy? Are those new interior walls looking less substantial than you expected? You're not alone.

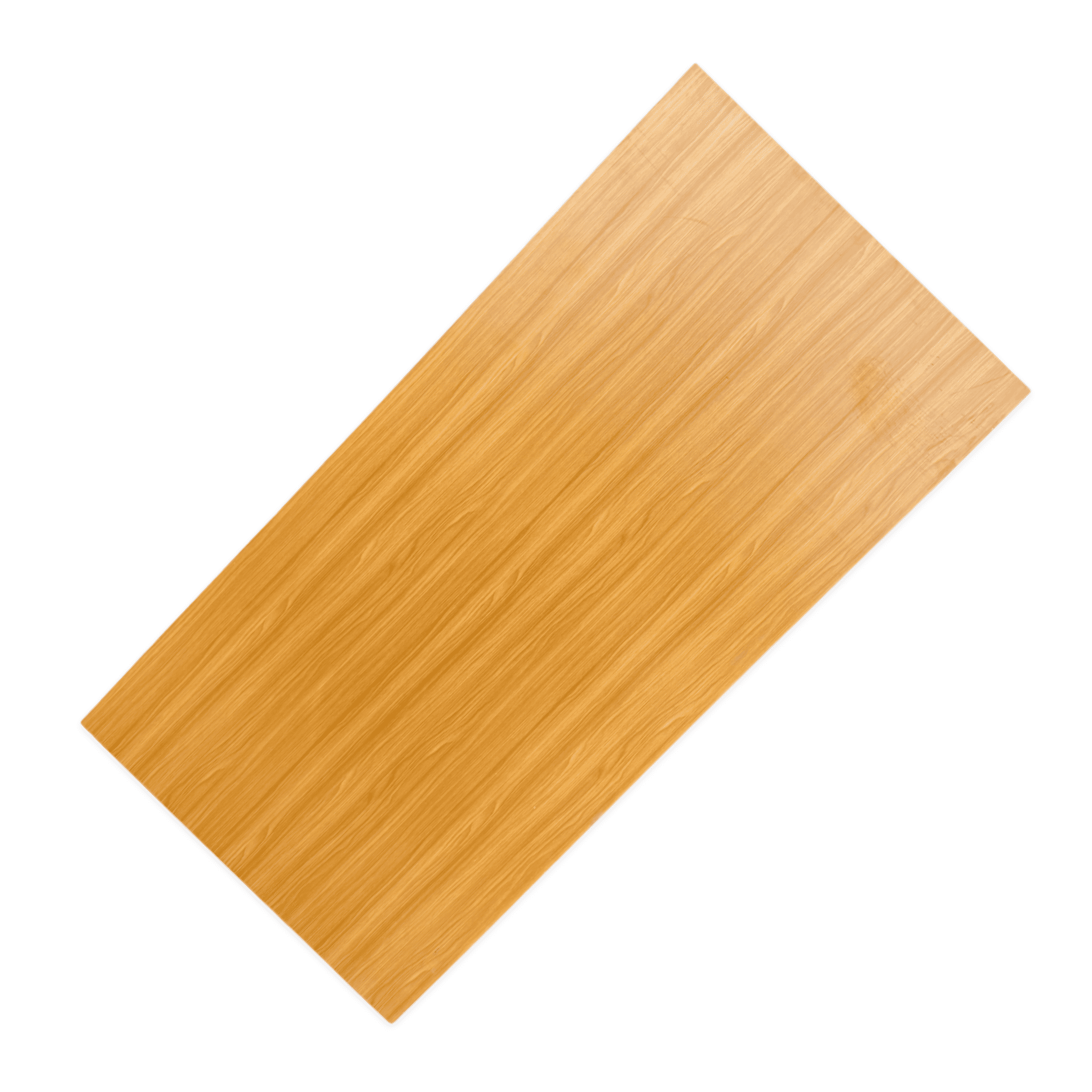

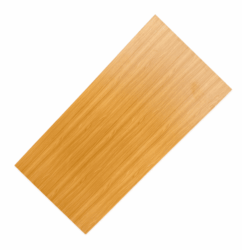

Across Nigeria, whispers are growing into concerned murmurs about the declining quality and, alarmingly, the physical dimensions of imported plywood and flute panels. These essential materials form the backbone of our booming furniture industry, construction sector, and even DIY projects. But are we getting what we pay for? Let's delve into the concerning issues plaguing the Nigerian market.

The Shrinking Feeling: It's Not Just Your Imagination

For carpenters, builders, and even hobbyists in Lagos and beyond, a standard size has always been a reliable measure. But increasingly, reports are surfacing of imported plywood and flute panels that fall short of these expected dimensions. We're talking about:

- Reduced Thickness: Plywood advertised as a certain millimeter thickness feels noticeably thinner, compromising its structural integrity.

- Shorter Lengths and Widths: Panels that should measure a standard 8ft x 4ft (or similar metric equivalents) are often slightly smaller, leading to wastage and requiring more pieces for a project.

- Thinner Flutes: Flute panels, prized for their decorative and sometimes acoustic properties, are appearing with shallower and less defined flutes.

Quality Taking a Dive: More Than Just Size

The issue isn't solely about the tape measure. The actual quality of the imported wood products is also raising red flags:

- Lower Density Core: Plywood often feels lighter and less dense, suggesting the use of lower-grade timber or more filler material in the core layers. This directly impacts its strength and screw-holding ability.

- Delamination Issues: Layers of plywood are separating more easily, even under minimal stress, rendering the material unusable. This points to poor adhesive quality or inadequate manufacturing processes.

- Surface Imperfections: Warping, knots, and uneven surfaces are becoming more common, requiring more preparation work and leading to a less professional finished product.

- Brittle Flute Panels: Flute panels are reported to be more prone to cracking and chipping, especially during cutting and installation.

The Ripple Effect: Who Pays the Price?

The reduction in quality and size has far-reaching consequences:

- Increased Costs for Businesses: Carpenters and furniture makers need to purchase more material to complete projects, increasing their overhead. They may also face higher rates of material wastage.

- Compromised Structural Integrity: Using undersized or low-quality plywood in construction can compromise the safety and longevity of structures.

- Disappointed Consumers: Furniture and fittings made with inferior materials are less durable and aesthetically pleasing, leading to dissatisfied customers.

- Impact on Local Manufacturing: While Nigeria has local plywood and panel manufacturers, the influx of cheaper, albeit lower quality, imports can create unfair competition.

Why is This Happening? Unpacking the Potential Causes

Several factors could be contributing to this concerning trend:

- Cost-Cutting Measures by Exporters: To offer cheaper prices, overseas manufacturers might be using lower-grade timber, thinner veneers, less adhesive, and reducing dimensions.

- Lax Import Regulations and Enforcement: Insufficient quality control at Nigerian ports could allow substandard goods to enter the market unchecked.

- Economic Pressures: The current economic climate might be pushing importers to prioritize cheaper options, even if it means sacrificing quality.

- Lack of Standardised Measurement and Quality Control: The absence of strict, consistently enforced standards for imported wood products makes it easier for these issues to persist.

Why is This Happening? Unpacking the Potential Causes

Addressing this issue requires a multi-pronged approach:

- Stricter Import Quality Control: The Nigerian government needs to implement and enforce rigorous quality standards for imported plywood and flute panels, including dimensional checks and material testing at ports.

- Consumer Awareness and Advocacy: Educating consumers and industry professionals to be vigilant about quality and to report substandard products can create pressure for change.

- Support for Local Manufacturers: Investing in and promoting Nigerian wood product manufacturers who adhere to quality standards can help create a more reliable domestic supply.

Industry Collaboration: Furniture associations, construction bodies, and other relevant stakeholders need to work together to address these issues and advocate for better standards.

The wood we use forms the foundation of so much in our lives, from the furniture in our homes to the structures we build. We cannot afford to let declining quality and shrinking sizes compromise safety, durability, and value for money. It's time for a closer look at the imported wood market and a renewed commitment to quality in Nigeria.

Have you experienced issues with the quality or size of imported plywood and flute panels in Nigeria? Share your experiences and insights in the comments below!

#Nigeria #Plywood #FlutePanels #BuildingMaterials #FurnitureIndustry #QualityControl #ImportRegulations #NigerianEconomy #Lagos

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.